Spinning wheels have been used to spin yarn and create textiles for centuries. However, with industrialization, using a spinning wheel has become a hobby rather than a way to keep your family warm. Whether you’re interested in this hobby or just want to know how your ancestors used to do it, you’re here because you asked how does a spinning wheel work?

A spinning wheel works by the spinner pushing the treadles (foot pedals) to spin the big wheel (drive wheel). This big wheel spins the flyer which adds twist to the fiber. Once twist is added to the fiber, the flyer pulls in the finished yarn and winds it onto the bobbin.

This is a simple version of how a spinning wheel works. The exact way that it works depends slightly on the type of spinning wheel that is being used but, the principle of adding twist to fiber to create yarn remains the same across all spinning wheels.

Without further ado, let’s get an in-depth look into how a spinning wheel works.

Table of Contents

Spinning Wheel Anatomy

Before we ask ‘how does a spinning wheel work’, we need to go over some basic anatomy of a spinning wheel so you know what the heck I’m talking about.

Treadles

The treadles of a spinning wheel are the pedals that a spinner uses to spin the wheel. My spinning wheel has been loved enough that you can see my footprint on the treadles but for some reason only the right one. I’ve tried to wash it off, it’s there forever.

The treadles are used by pushing them up and down with your feet. It’s actually pretty relaxing once you get into a rhythm.

Some wheels have one and some wheels have two treadles. But, regardless of the number, the treadles do the same thing.

The treadles are attached to an arm that pushes the drive wheel up and down. Pretty simple which makes it even cooler.

Now that we know how it’s powered let’s talk about what the treadles move.

Drive Wheel

The drive wheel is the big wheel on a spinning wheel. They come in numerous shapes and sizes including some spinning wheels that have gigantic drive wheels.

The drive wheel is spun by peddling the treadles. It is connected to the flyer, which we’ll talk about next, by the drive band which you can see going all the way around the drive wheel.

This band imparts the power and spin of the drive wheel to the flyer. Now, let’s talk about what the flyer does with all that power.

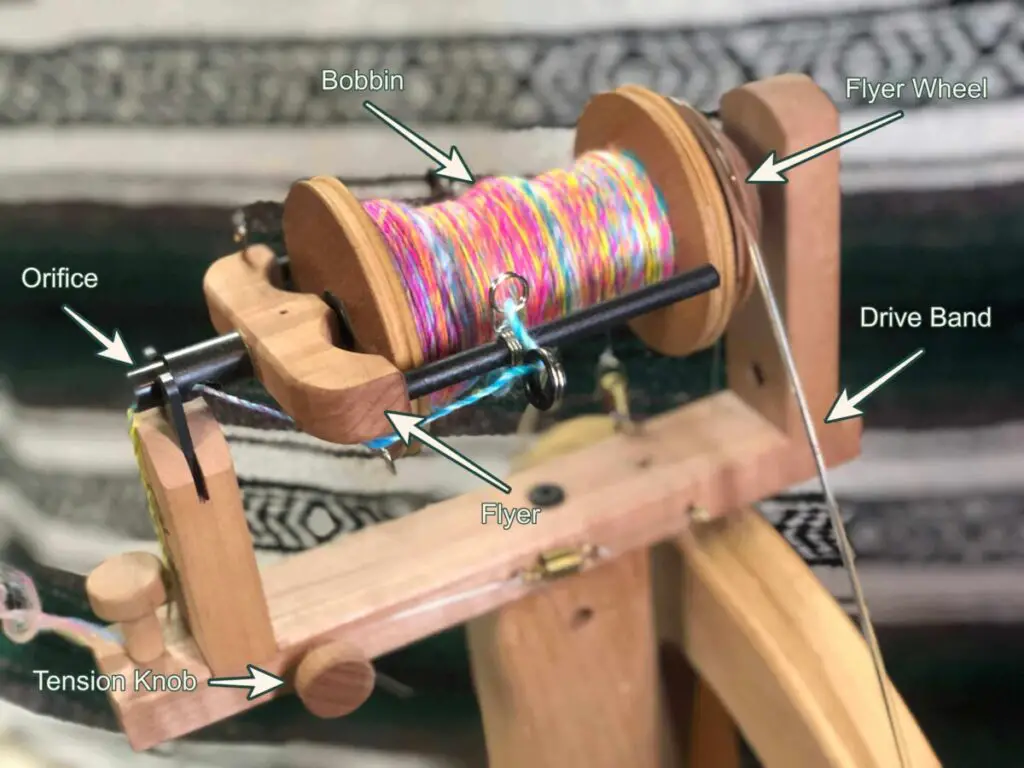

Flyer and Flyer Wheel

The flyer wheel is the smaller wheel on the spinning wheel and is usually connected to the bobbin in some way. You can see my flyer wheel at the end of the bobbin with the drive band around it.

The flyer is the name for the arms that go around the bobbin and wind the yarn onto the bobbin.

The flyer wheel is connected to the drive wheel by the drive band. When the drive wheel spins, that same spin is imparted to the flyer wheel which spins the flyer.

The flyer spinning is what adds twist to the fiber that is being spun. Then, once enough twist is added, the finished yarn is pulled in and wound onto the bobbin by the flyer.

Bobbins

The bobbin is basically just the thing that holds the finished yarn.

The flyer arms surround the bobbin and spin the finished yarn onto the bobbin. Bobbins can come in many different shapes and sizes.

If you’re making chunky art yarn you might need a bigger bobbin so you can hold more yarn. Bobbins are also specific to the wheel and aren’t usually interchangeable.

Tension/Brake Band

Last but not least, all wheels have a tension band, also called a brake band. The brake band goes around the bobbin on the wheel and creates resistance between the flyer and the fiber supply the spinner is holding.

If you have really high resistance, the flyer will pull the fiber onto the bobbin much harder, if it’s low or none, the flyer won’t pull it onto the bobbin at all.

If your brake band is set too high it can yank the fiber right out of your hands while you’re working. So, it’s important to keep an eye on it and adjust it as needed while spinning.

Now that we’ve got the basic spinning wheel anatomy out of the way, let’s get into the question that you came here to ask: How does a spinning wheel work?

How Does a Spinning Wheel Work?

When it gets right down to it, spinning yarn is actually really simple.

Yarn is just twisted fiber. It can be made out of any kind of fiber; from wool to silk to banana fiber.

A spinning wheel works by adding twist to fiber to create yarn. It does this by using all the things we talked about in the anatomy lesson.

To begin, the spinner will have the fiber of choice hooked up to the wheel, the spinner will then push the treadles at their chosen speed.

The treadles will spin the drive wheel which spins the flyer which adds twist to the fiber the spinner is holding.

The spinner will control the fiber and draft out fibers to create the desired thickness of yarn.

Then, when the fiber the spinner is holding has been converted into the kind of yarn the spinner wants, the spinner will move their hands forward and the flyer will wind the finished yarn onto the bobbin.

The spinner repeats this process until they run out of fiber or until the bobbin is full. Then, they’ll remove the bobbin from the wheel.

This fresh one-stranded yarn is called a single in the craft world. Now, the spinner can decide if they want to leave it as a single, or if they want to ply the yarn.

Plying is just a fancy word for twisting two or more singles together. When a yarn is plied, it makes it stronger.

Plying is also done using a spinning wheel, you just repeat the process above except instead of using fiber, you use two or more singles held together.

And there you have it, the science behind how a spinning wheel works. I hope you weren’t disappointed with how simple it was! Sometimes simplicity is the best way to go.

Wrap Up

Alrighty! Thank you for coming with me on this educational journey. I hope you learned something about the ancient art of spinning but just to make sure you didn’t miss anything let’s do a quick recap.

First, we went over some basic spinning wheel terminology so you could understand all the strange words used in the spinning world.

Then, we put it all together to learn how a spinning wheel works.

We learned that the treadles spin the drive wheel, which spins the flyer, which adds twist to the fiber. Then, the finished yarn is pulled in and wound onto the bobbin by the flyer.

Boom! Super simple yet so smart in how much it can make.

Now that you know the clever simplicity of a spinning wheel, go out there and make something awesome!